Chemical oil refining of edible oil refers to the process of using chemical methods to remove impurities in edible oils and fats to improve the purity and quality of oils and fats. The following is a detailed introduction to the chemical refining of edible oils: I. Process Overview of chemical oil refining The chemical refining …

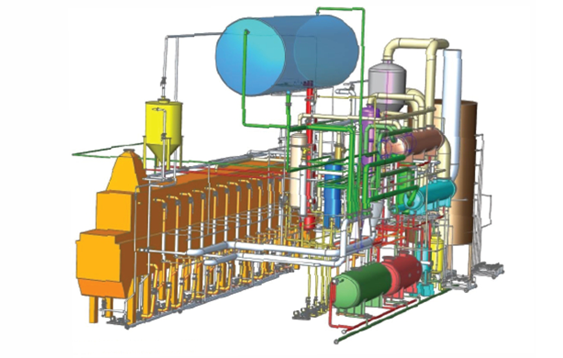

Chemical oil refining