Concept and process of winterization of oils and fats

Winterization of oils and fats is a method of crystallization separation. By cooling the oils and fats to 4-6℃, glycerides with higher freezing points are crystallized and precipitated, thereby separating the oil and solid fat. This process usually takes 24 hours of cooling time, and the oil and solid fat are separated by filtration. Winterization of oils and fats is often used for oils and fats such as cottonseed oil. After degumming, deacidification, decolorization, and deodorization, a small amount of solid fat will still precipitate in winter, affecting the appearance and use.

Advantages and disadvantages of winterization of oils and fats

The advantage of winterization of oils and fats is that it can improve the transparency and stability of oils and fats, and is suitable for food processing industries that require high-quality oils and fats. However, the process requires specific equipment and controlled cooling speed, which increases production costs. In addition, the solid fat after winterization of oils and fats can be separated by filtration, but the temperature and pressure need to be controlled during the filtration process to avoid destroying the crystal structure.

Oil winterization fractionation technology can generally be divided into 3 categories:

1. Dry fractionation (Dry franctionation), also known as natural fractionation.

2. Solvent fractionation (Solvent franctionation).

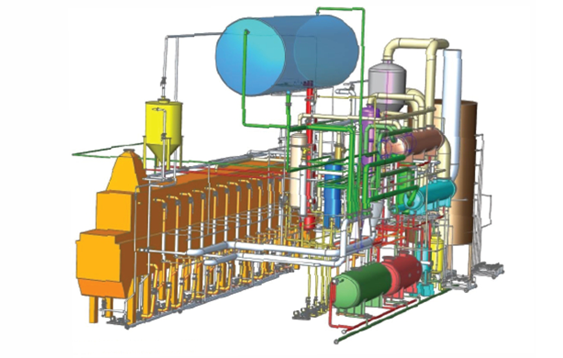

3. Surfactant fractionation, also known as emulsification fractionation. Dry fractionation is the most common and commonly used fractionation technology. It is to completely melt the oil into liquid oil without adding any solvent, stir it at a low speed, and slowly cool it to a certain temperature, so that the solid fat components in the oil will be crystallized first, and then the solid and liquid phases will be separated. Solvent fractionation is to dissolve the oil in a certain proportion with an organic solvent (such as n-hexane, acetone, etc.) and then winterize it, so that the solid fat crystallizes and separates it. Although the effect of solvent fractionation is better than that of dry fractionation, it generally requires a lower winterization temperature than dry fractionation, and consumes a large amount of organic solvents that are harmful to human health. Surfactant fractionation is to add a certain proportion of surfactants (such as sodium dodecyl sulfate, etc.) and water or electrolyte (such as sodium chloride, magnesium sulfate, etc.) aqueous solution to the oil after the crystals are precipitated by dry winterization, so that the crystallized solid fat is emulsified and suspended in the water phase, thereby accelerating the separation efficiency of crystallized solid fat. Surfactant fractionation is more efficient than dry fractionation and is suitable for large-scale production; however, since many surfactants are not allowed to be used in edible oil processing, their practical application is limited and not widely used.

Winterization of common vegetable oils

1. Cottonseed oil

Cottonseed oil contains 21.6%-24.8% palmitic acid and 1.9%-2.4% stearic acid, and has a high melting point. First heat the oil to 30-40℃, then send it to the crystallizer. The crystallizer uses cooling water to cool the oil to 15-20℃, and uses chilled water to cool it to 6-8℃. Cultivate the crystals in the crystallizer for 12-24h, and stir at a speed of 10-15 r/min to form β’ crystals with larger particles, high hardness and easy separation. This is a stable crystal. For cottonseed oil dewaxing and filtration, a membrane filter should be used, with a membrane of 0.7 MPa, a filtration pressure of 0.2-0.4 MPa, and a maximum working pressure of 0.5 MPa. Dry dewaxing and degreasing can separate 75% of liquid oil and 25% of solid fat.

2. Sunflower oil

Use rapid cooling to cool the sunflower oil to 8°C in 1 minute through a heat exchanger. The wax crystals are flake-shaped. After filtration, the wax content of the oil is less than or equal to 80 mg/kg. Small crystals contain less oil and are well dispersed in water, which is beneficial for separation. Rapid cooling is conducive to the formation of small crystals. The crystallization and crystal growth time is generally 12 hours. (More Sunflower oil refinery machine)

3. Rapeseed oil

Rapeseed oil contains 20-400 mg/kg of waxy compounds, of which 60%-80% are waxy. The crystallization characteristics are difficult to detect, and sometimes precipitation occurs after several days or months. The decolorized oil is rapidly cooled to 5℃, crystallized for 24h, and 0.1% filter aid is added to the filter to remove high melting point long chain fatty acid wax and solid fat.

4. Corn oil

Corn oil generally contains about 500 mg/kg of wax, and the acid value of alkali refining KOH is controlled at 0.2-0.25mg/g. 0.2% filter aid is added to the decolorized oil, and it is rapidly cooled to 5-10℃, the stirring speed is 10-13 r/min, and the crystallization time is 8-12h. It is best to dewax first and then deodorize, so as to avoid the acidity of the filter aid during filtration, which will increase the acid value of the oil and exceed the acid value index of small package oil. The oil temperature in the deodorization tower is controlled at 230℃.

5. Rice bran oil

(1) First-grade rice bran oil

Rice bran oil has a high solid fat content, including 1%-3.8% stearic acid and 12%-18% palmitic acid. Solid fats crystallize and precipitate at low temperatures, making the oil turbid and causing solid-liquid stratification. Degreasing should be done after deacidification, otherwise fatty acids will crystallize and solidify before lipids at low temperatures, making degreasing and filtration impossible. After physical refining, the rice bran oil has an acid value of 1-3 mg/g. It is cooled to 30°C and pumped into a degreasing crystallization tank. After 24 hours, it is slowly and evenly cooled to 0-2°C and kept warm for 48 hours. Slow stirring is used during the crystallization process. During the crystallization process, the temperature is allowed to rise slightly by 2-5°C. The oil is then filtered using a filter pre-coated with diatomaceous earth. The filter pressure of the pre-coating is about 0.06MPa and the filtration temperature is set at 25°C. Natural filtration is performed using the oil level difference and gravity difference, avoiding the use of a pressure-assisted filtration pump with strong shearing and stirring action, which can easily break the fat crystals. Physically refined rice bran oil is dewaxed and defatted to obtain about 90% liquid oil and 5%-10% solid fat (containing a small amount of liquid oil). Another method is to crystallize and filter twice. The deodorized rice bran oil is cooled to about 30℃, cooled and crystallized for 24 hours, filtered once, and the filter pressure is less than or equal to 0.35MPa. The filtered oil enters the second crystallization tank. When the oil temperature is less than or equal to 25℃ and the crystal is grown for 24 hours, it is filtered twice and the filter pressure is less than or equal to 0.35MPa.

(2) Three and four levels of rice bran

The dewaxing of rice bran oil is arranged before bleaching. The free fatty acid content in the oil is high, the acid value KOH is about 30mg/g, and the fatty acid melting point is high. As the temperature decreases, the fatty acid solidifies first, causing the viscosity of the oil to rise sharply. At 20℃, the rice bran oil is very thick, and dewaxing and filtering are difficult. Therefore, the filtration temperature should be greater than or equal to 20℃. After dehydrating the rice bran oil, pump it into the crystallization tank and stir it slowly. Cool the oil temperature from 70℃ to about 25℃ within 24h, continue to stir slowly (10-15r/min), maintain the oil temperature for 48h, and then pump it into the leaf filter for filtration. The filter is pre-coated with diatomaceous earth before the oil enters. Increasing the filtration temperature can speed up the filtration speed and reduce the oil content in the wax paste, but the transparency of the oil becomes worse; lowering the filtration temperature and the filtration speed will decrease, reducing the wax content in the oil, lowering the cloud point, and improving the transparency of the oil. The liquid oil is about 90%, and the solid fat is 5%-10%. Dewaxing rice bran oil has a certain decolorization effect. Production shows that the color of Y70 and R20 rice bran oil drops to Y70 and R12 after dewaxing. The reason is that the brown trivalent iron ions and fatty acid chelates and some pigments with higher melting points crystallize and precipitate at low temperatures, and are trapped in the wax during dewaxing and filtration.